Flexible networking, monitoring and automation

The Edge Controller iPCR connects devices and equipment on-site. Sensor data are processed decentrally on the iPCR enabling diverse applications in automation, plant monitoring, load management and predictive maintenance via artificial intelligence. The common denominator is freely programmable logic and algorithms enabling individual solutions on the iPCR - implemetbed by deZem or the customer himself.

The Edge Controller communicates with the field level via a variety of protocols and hardware interfaces, e.g. with meters, actuators, PLCs, and control systems. Supplementary sensors e.g. wireless, waterproof temperature and vibration sensors, with extremely low energy consumption are quickly installed.

If required, the iPCR transfers data in real-time, e.g. to the deZem data platform. Versatile dashboard for visualisation and control are available directly on the iPCR.

The iPCR is a compact, fanless industrial PC. Different hardware models are available covering a wide range of application scenarios - all models featuring the same software based on the deZem OS. Regular software updates Over-The-Air (OTA) are a matter of course.

Why the deZem iPCR?

- Flexible usage scenarios in control and monitoring

- Edge computing with freely programmable logic plus AI

- Dashboards on the iPCR

- Connection of sensors, actuators, meters, measurement devices etc. via various field buses and interfaces

- Read out hundreds of data sources with one iPCR

- Data transmission to other platforms via Ethernet, WiFi or mobile communication

- Over the Air (OTA) Updates

- Time resolution of metered values up to 1 s

What our customers say

Our 5-year experience with the iPCR is consistently positive.

Recently, deZem supported us on short notice with a tailor-made solution: A control signal for our new CHP plant is generated from the metered values in order to produce the required energy with pinpoint accuracy.

Private dairy Naarmann GmbH

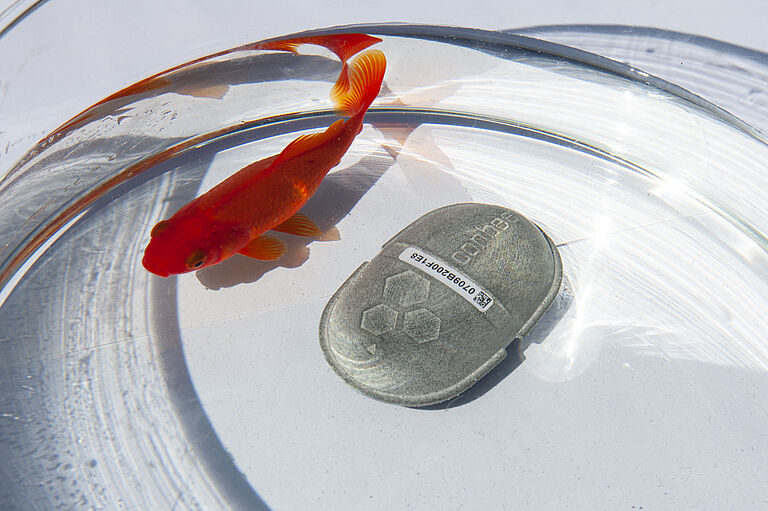

IoT Sensors for the iPCR

The great potential of the iPCR unfolds itself when machines and equipment are upgraded with additional IoT sensors. IoT sensors are wireless, small, waterproof and quick to install. They have a battery life of 10 to 15 years or are even energy self-sufficient.

Possible measurements:

- Temperature

- Humidity

- Vibration

- Electricity

- Weather data

iPCR application scenario examples

Load Management

Switch load on and off automatically to avoid undesired peaks.

Greenhouse control

Fully automated closed-loop control based on local and external data, e. g. weather.

Predictive maintenance

Identify discrepancies and anomalies at an early stage in order to rectify the cause prior to equipment failure.

Metering case for special solutions

Special applications for temporary and mobile use with graphic display. Ideal for short-term automation and monitoring projects.